Quality Control for Plastics and Rubber Products

Industries Covered

- Packaging and Containers Manufacturing

- Automotive Components (e.g., seals, hoses, and bumpers)

- Consumer Goods (e.g., toys, household items)

- Medical Devices and Equipment

- Industrial Machinery Components

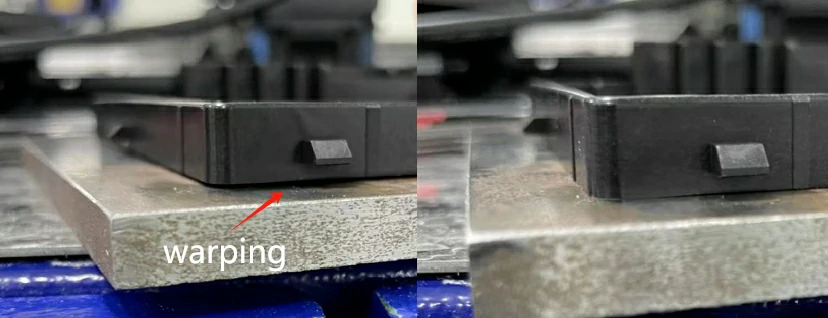

Part Inspection

Surface finish, dimensional accuracy, flash, warping, shrinkage.

In-Process Inspection

Monitoring extrusion or molding for defects, checking cooling rate.

Operation Missing Inspection

Trimming, drilling, or hole alignment.

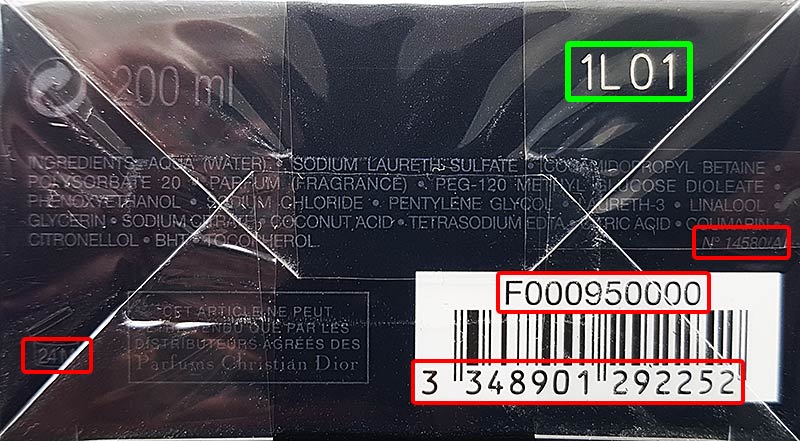

Label Inspection

Checking engraved or printed batch codes, recycling symbols.

Assembly Inspection

Verification of multi-part plastic or rubber products (e.g., seals, gaskets).

Material Consistency Check

Homogeneity of rubber or plastic blends.

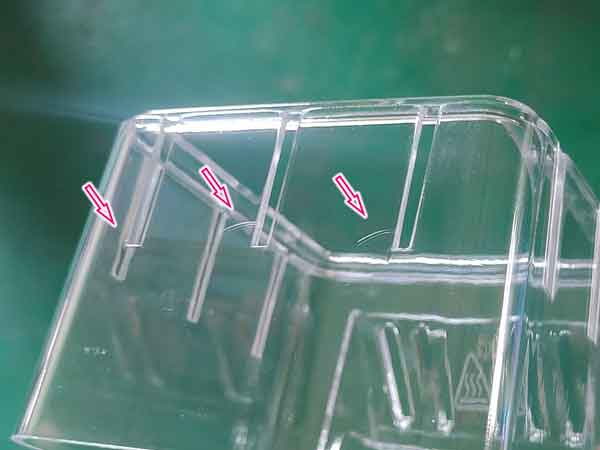

Weld Line Inspection

Ensuring integrity of molded weld lines.

Color Uniformity Inspection

Detecting color deviations in plastic parts.

Durability Testing

Ensuring proper elasticity, flexibility, and hardness.

Why QUALVIZ

QualViz provides a highly intuitive, user-friendly software environment, making it accessible to users without any programming expertise. The platform comes preloaded with all essential modules for industrial visual inspection. It offers seamless compatibility with a wide range of hardware brands, supports both Windows® and Linux® operating systems, and runs efficiently on embedded devices.

QualViz accelerates deployment with predefined output rules, enabling quick and efficient integration into your systems. Additionally, we collaborate with a global network of trusted partners to assist you in selecting the right hardware tailored to your business needs. Our team ensures smooth integration into your existing company-wide infrastructure.

We prioritize understanding your specific requirements to deliver tailored solutions that meet your unique needs. Our comprehensive support includes a free feasibility study, a 30-day free trial, expert guidance during and after deployment, and hands-on training to help your team maximize the potential of QualViz.