Precision Inspection for Metal and Machined Parts

Industries Covered

- Automotive and Aerospace Parts Manufacturing

- Fasteners and Tools Production

- Sheet Metal Components Manufacturing

- Heavy Machinery and Equipment

- Defense and Marine Engineering

Part Inspection

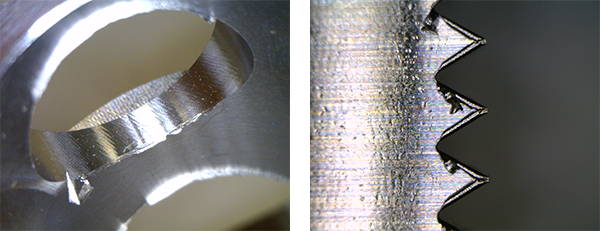

Surface finish, flatness, burrs, or edge defects.

In-Process Inspection

Monitoring CNC machining or stamping for anomalies.

Operation Missing Inspection

Detection of missing threads, drilling, or other operations.

Label Inspection

Engraved, stamped, or laser-marked serial numbers or codes.

Assembly Inspection

Verifying fit and function of assembled parts.

Welding Quality Inspection

Checking seam uniformity and strength.

Alignment Inspection

Verifying proper alignment of machined components.

Coating Thickness and Uniformity Inspection

Ensuring correct application of paints or protective coatings.

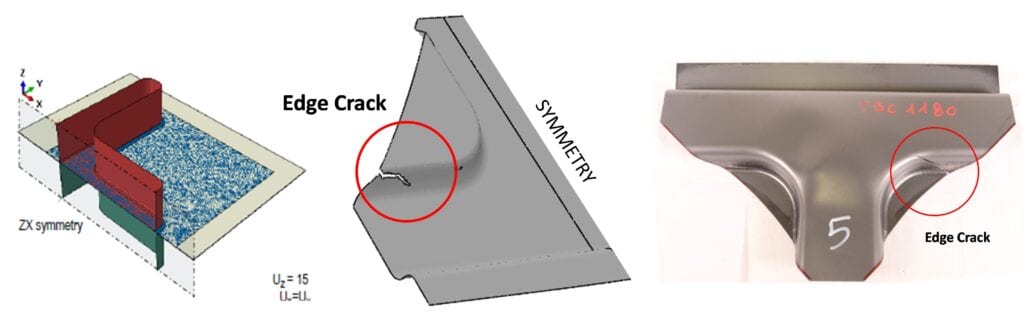

Structural Integrity Testing

Stress or load-bearing capacity checks.

Hole Position and Diameter Inspection

Ensuring accurate drilling or punching.

Why QUALVIZ

QualViz provides a highly intuitive, user-friendly software environment, making it accessible to users without any programming expertise. The platform comes preloaded with all essential modules for industrial visual inspection. It offers seamless compatibility with a wide range of hardware brands, supports both Windows® and Linux® operating systems, and runs efficiently on embedded devices.

QualViz accelerates deployment with predefined output rules, enabling quick and efficient integration into your systems. Additionally, we collaborate with a global network of trusted partners to assist you in selecting the right hardware tailored to your business needs. Our team ensures smooth integration into your existing company-wide infrastructure.

We prioritize understanding your specific requirements to deliver tailored solutions that meet your unique needs. Our comprehensive support includes a free feasibility study, a 30-day free trial, expert guidance during and after deployment, and hands-on training to help your team maximize the potential of QualViz.