Inspection for Electronics and Components

Industries Covered

- Consumer Electronics (e.g., smartphones, TVs)

- PCB and Semiconductor Manufacturing

- Automotive Electronics (e.g., sensors, ECUs)

- Medical Electronics and Devices

Part Inspection

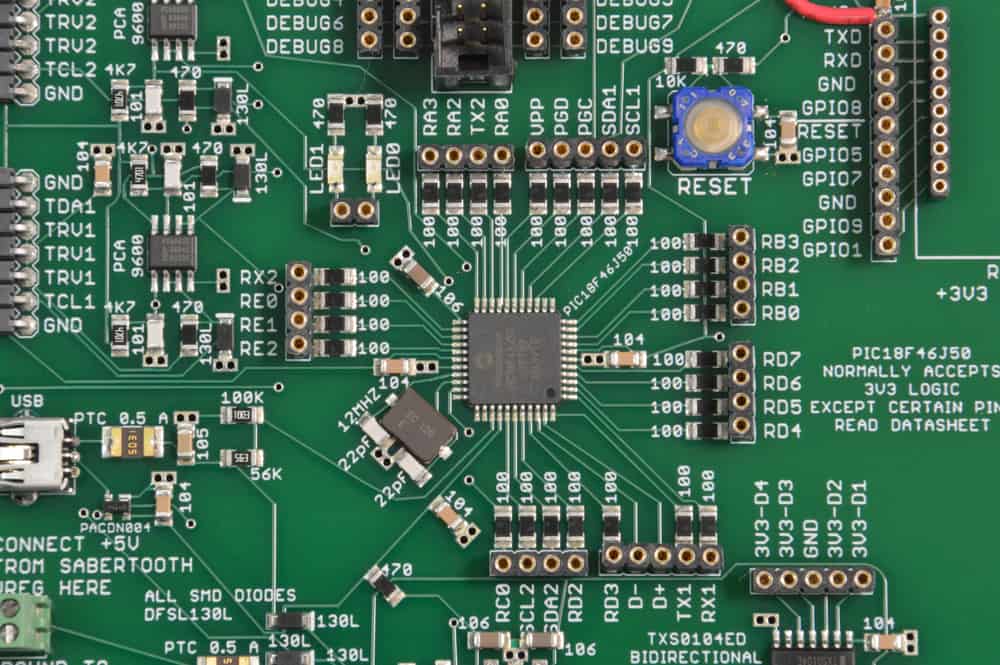

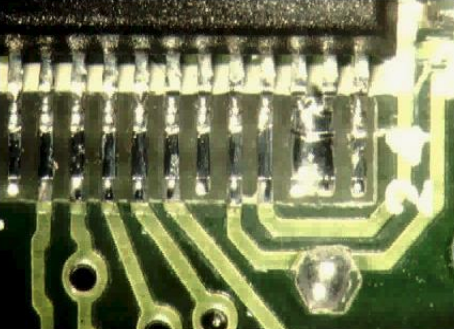

PCB tracks, solder joint quality, or component placement.

In-Process Inspection

Monitoring assembly lines for real-time defects.

Operation Missing Inspection

Detecting missing seals, caps, or desiccants.

Label Inspection

Barcode verification or component labeling.

Assembly Inspection

Ensuring correct orientation and placement of components.

Continuity Testing

:max_bytes(150000):strip_icc()/testing-single-pole-switches-1152811-05-f73984fcd6ba47cca19a274399b87081.jpg)

Ensuring electrical connections are intact.

Thermal Inspection

Checking for overheating components.

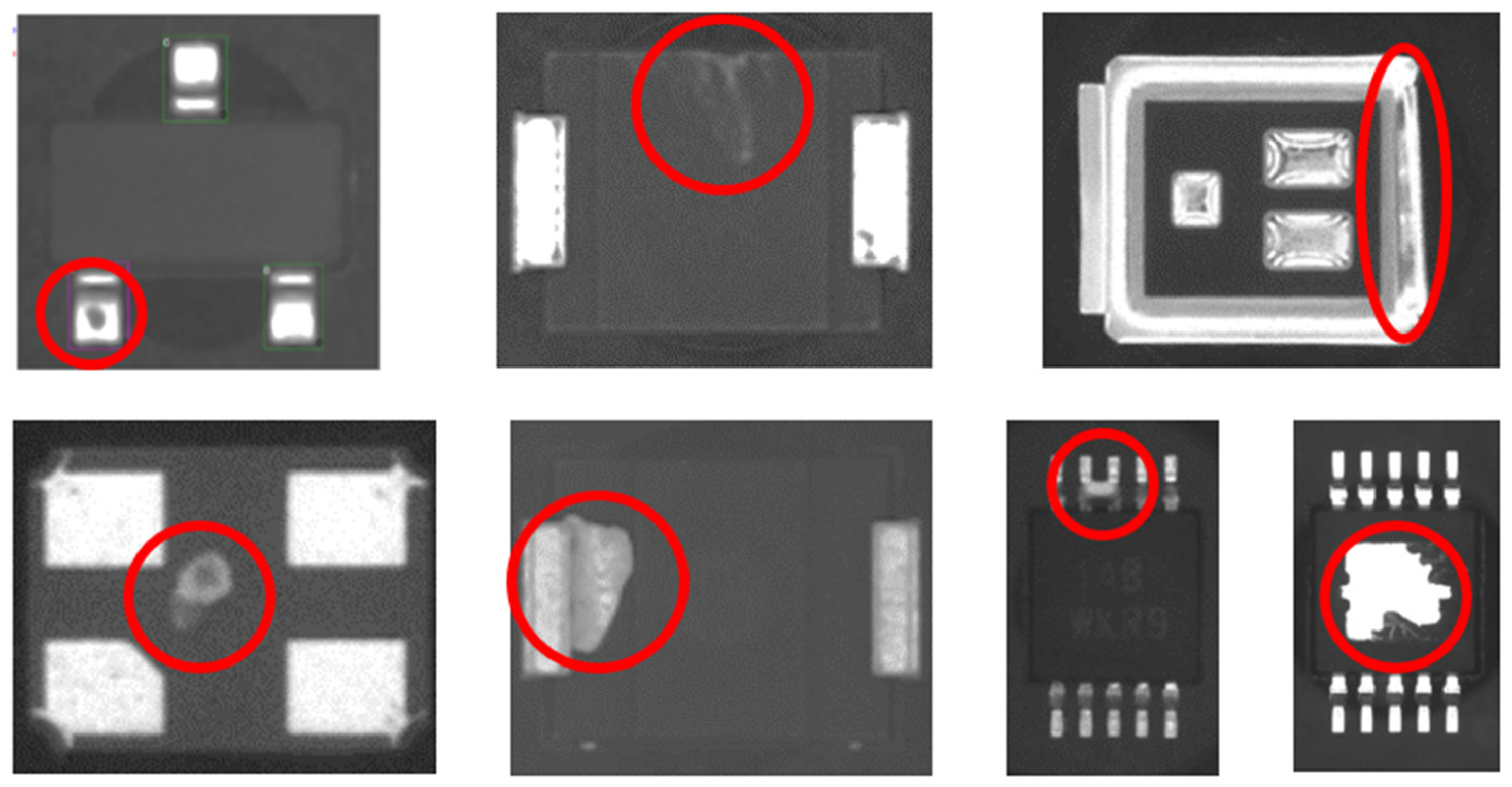

Die Bond Inspection

Ensuring semiconductor chips are securely attached.

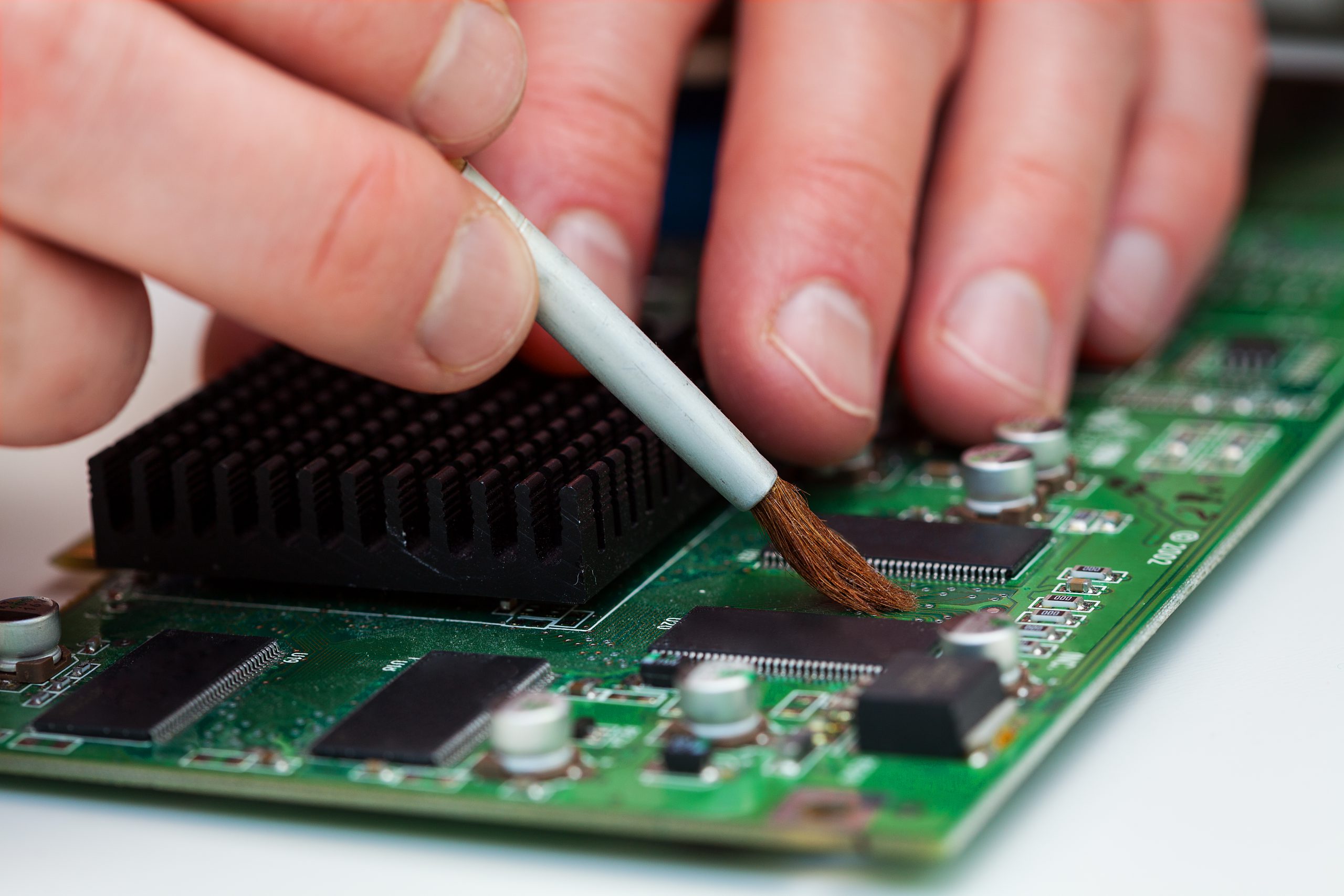

Coating and Conformal Layer Inspection

Verifying protective layers.

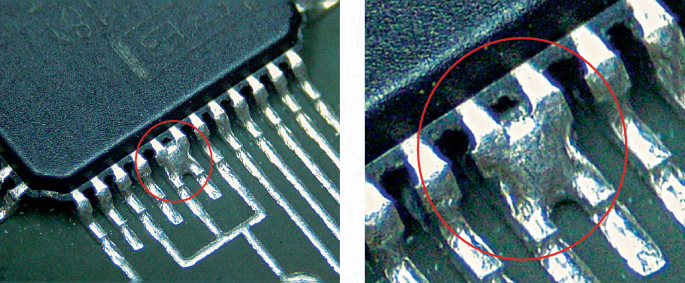

Short Circuit Detection

Identifying defective solder bridges.

Why QUALVIZ

QualViz provides a highly intuitive, user-friendly software environment, making it accessible to users without any programming expertise. The platform comes preloaded with all essential modules for industrial visual inspection. It offers seamless compatibility with a wide range of hardware brands, supports both Windows® and Linux® operating systems, and runs efficiently on embedded devices.

QualViz accelerates deployment with predefined output rules, enabling quick and efficient integration into your systems. Additionally, we collaborate with a global network of trusted partners to assist you in selecting the right hardware tailored to your business needs. Our team ensures smooth integration into your existing company-wide infrastructure.

We prioritize understanding your specific requirements to deliver tailored solutions that meet your unique needs. Our comprehensive support includes a free feasibility study, a 30-day free trial, expert guidance during and after deployment, and hands-on training to help your team maximize the potential of QualViz.